Flexport Insights Collection - Volume 1

Scenario Planning

for Success

A Step-by-Step Guide

A Note from Mathijs

At Flexport, we see opportunities to make global trade easier – for both businesses and their customers. In short, our mission is to make global commerce so easy, there’s more of it. And a key part of that involves accurate and adaptable scenario planning.

While you can set a clear plan for the coming months, surprises are inevitable. But with the right insights and preparation, you can navigate those unexpected events more effectively. This doesn’t mean you have to manage and control everything, but when you adapt faster than your competitors, the results show in your bottom line.

In this series, we’ll share insights from our experts and the wider market to help you prepare for what’s next. We’ll give you practical tools, structured approaches, and scenarios to help you gain a better understanding of the complexities and barriers involved in global trade.

The future belongs to those who anticipate change, not just react to it.

Introduction

With rising geopolitical tensions, economic shifts, and rapid tech advancements, managing crises is more important than ever. For example, if a key supplier shuts down tomorrow or new trade restrictions suddenly disrupt your supply chain, you need to know how to adapt.

Using scenario planning that combines granular industry insights with your own data, you can create clear strategies for handling potential disruptions – and even turn those disruptions into strategic advantages.

Scenario planning can help you build resilience and flexibility into your operations, so you can stay on track, resilient, and agile, no matter what happens.

The Importance of Scenario Planning

Scenario planning replaces static predictions and instead acts as a toolkit of customized backup plans and contingencies for unexpected situations – helping you build supply chain resilience.

With response procedures in place, you can better manage risks, and make faster, more informed decisions when responding to disruption.

This guide will show you how scenario planning can work as part of your broader strategy planning framework. The following four steps will show you how to apply it to your supply chain, and help you prepare for the future and your next round of RFPs.

Get a Head Start On Your Scenario Planning Strategy

Flexport experts share their advice on why scenario planning is so crucial, and the tactics you can start implementing right now.

Step 1: Driving Forces

The first step of any scenario planning strategy should be to set clear objectives and build the right team. This involves identifying the critical questions facing your supply chain and the outcomes you need to prepare for.

Your team should include representatives from your supply chain, corporate strategy, finance, IT, and HR. Each member will bring unique insights on trends, dependencies, and risks, ensuring the strategies you build are well-rounded and practical.

From that point, you’ll be well-positioned to identify the driving forces affecting your supply chain. We recommend using the PESTEL model to create a complete view of the environment your business operates in, document the potential impacts, and consider solutions.

PESTEL recognizes every factor that impacts global trade and supply chains to help you assess potential risks and prepare the right response. Take a look in the chart below.

Political influences on trade come in the form of geopolitical risks and violence, such as those seen today in continuing conflicts in the Middle East and Ukraine. Monetary policy has an economic impact across supply chains – particularly influencing pricing – and can be linked to labor unrest in places like Canada and the US, and changing customs regulations worldwide.

E-commerce growth and the influence of social media are representative of new consumer behaviors reshaping global demand. Meanwhile, the digital transformation of supply chains by artificial intelligence (AI) technologies and automated trade processes increases the threat of cyber-attacks.

Trade policies are guiding firms’ legal processes, particularly following the US election and its implications for protectionist measures. Environmental regulations, including emissions trading systems, are driving change – especially in the European Union, where the Green Deal has imposed new sustainability laws on companies.

While this list isn’t exhaustive, it’s a great place to start considering the various driving forces that can impact your business.

Step 2: Critical Uncertainties

The driving forces we’ve covered – from political influences to trade policy changes – can all influence organizations in unpredictable ways, creating critical uncertainties that could impact supply chains. Analyzing the most likely outcomes is essential because they’ll determine how the resulting scenarios and response strategies will play out.

Within the logistics sector, three main critical uncertainties will determine organizations’ responses to market and industry changes: reliability, space, and cost.

Critical Uncertainties

Reliability

The reliability of ocean, air, and land freight is crucial to ensuring shipments arrive at the right place, at the right time. This depends on various inputs, including port and airport efficiency, network structures, and supply chain connectivity – all of which are sensitive to external factors from the PESTEL model.

Critical Uncertainties

Space

Available capacity on planes, ships, trucks and in warehouses will be critical in the coming months and years. Economic and geopolitical tensions will likely add strain to already stretched supply chains, directly impacting capacity. You’ll need to carefully plan your requirements to ensure you can manage the constraints sustainably.

Critical Uncertainties

Cost

The cost of transporting goods, especially freight rates, is a crucial element of effective supply chains. However, it is important to factor in additional costs tied to the overall efficiency and flexibility of your logistics operations.

By gathering insights from your team, suppliers, and key customers, you’ll build a well-rounded view of all three of these uncertainties. You’ll also be well-positioned to create realistic, flexible scenarios that keep your supply chain resilient.

To Access the Flexport Rate Sheet, Contact Us Today

Our spreadsheet-based tool is designed to indicate the cost implications of various rate scenarios, considering each customer’s business and the seasonality of its products. Click the button below or send an email to helloeurope@flexport.com

Step 3: Develop Scenarios

Now that you’ve mapped out the driving forces and critical uncertainties your business faces, you can start modeling possible scenarios specific to your business.

This should consider a wide range of potential scenarios that could unfold based on multiple combinations of uncertainties, not just the most likely disruptions. If you narrow your scope too much, you might miss out on some helpful response ideas.

For each scenario, consider what it would mean for the costs, reliability, and space in your supply chain. Make a list of the events that would need to happen for this scenario to play out, and note what’s unlikely to happen – this helps clearly differentiate scenarios.

With a broad-brush look at potential scenarios, you can calculate how likely each one is, and begin focusing on those most probable. This isn’t about prescribing exact probabilities; it’s more about getting your team’s consensus on what could realistically happen.

Also, some scenarios could even happen together, so your probabilities wouldn’t necessarily add up to 100%.

It’s a process that will require accurate and high-quality data – the accuracy of your scenarios will only be as good as the accuracy of your data. But if done correctly, you’ll end up with a robust set of realistic, well-rounded scenarios that’ll help you prepare for whatever comes next.

Watch Our Latest Webinar on Scenario Planning

In a recent webinar, we looked back on some real-world scenarios and discussed solutions. Catch up now.

Step 4: Implications and Paths Forward

The Rapid Response Model

The final stage involves creating a response plan you can use to manage any scenario swiftly and effectively.

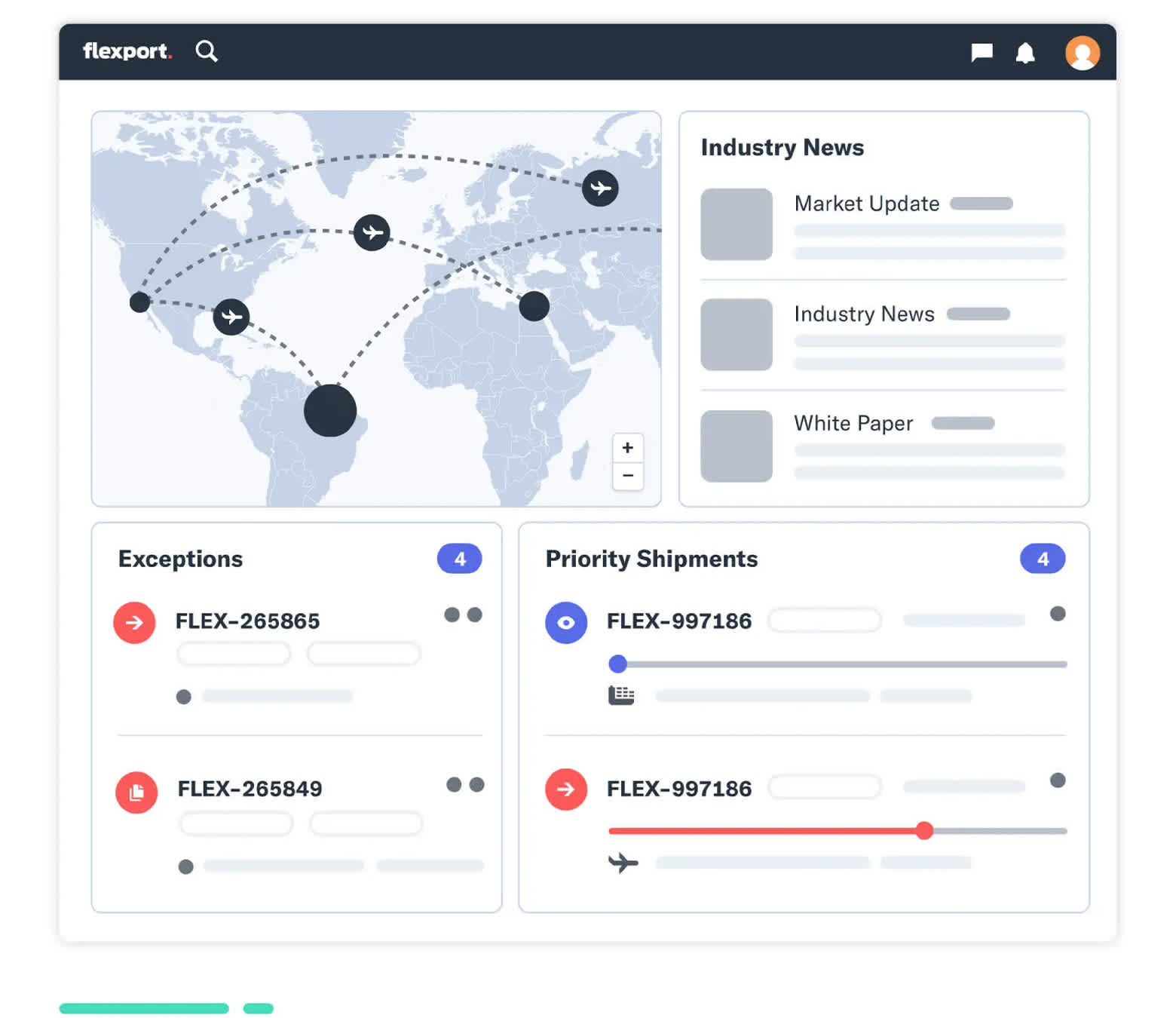

Flexport’s Rapid Response Model (pictured below) can help you establish both long- and short-term actions tailored to each of your scenarios. The model uses high-quality, well-distributed data to guide your responses, giving you insights on both what’s happening right now and historical trends to spot developments early.

With the right data, you’ll be able to answer questions such as:

- What happened?

- What will result from that?

- And what should we do in response?

From a process perspective, the model ensures everyone in your supply chain has visibility and access to clear, actionable steps. End-to-end integration allows for smooth, robust processes that can adapt to changes without missing a beat.

By combining data and process in this way, the model can empower your team to handle any scenario that comes your way.

The Checklist

Before deploying the Rapid Response Model, take a moment to assess your readiness for each scenario and determine if you have the right capabilities in place to respond.

Crucially, in each scenario, you’ll need to find the balance between short-term quick fixes and long-term strategies.

You can use this helpful checklist to identify actions you can take to strengthen your current capabilities and ensure you’re prepared for whatever happens.

This checklist shouldn’t just be about ticking boxes, either. Instead, it should act as a roadmap to resilience. If you can ensure you’re equipped in these areas, you’ll be ready to handle any scenario no matter how complex.

If you’d like to discuss your own readiness for scenarios specific to your business, feel free to get in touch for a free consultation or send an email to helloeurope@flexport.com.

Conclusion

In a world where disruptions can strike without warning, scenario planning is a crucial tool to help you prepare for whatever happens.

With the right approach to scenario planning, you can assess your organization’s readiness and rapidly identify the actions you need to protect your future.

The insights you’ll gain aren’t just informative; they’re indispensable for constructing RFPs that reflect true resilience, helping you face a volatile landscape head-on.

The model we’ve outlined is also fully customizable to your own supply chain dynamics, so your teams can make calculations tailored to their specific activities and receive the actions they need to respond. This will become especially crucial during the design stage of your RFPs, where you’ll be able to provide critical metrics on factors such as your preparedness to respond to specific events, your supply chain teams’ data capabilities, and their shipping rate forecasts.

In such a volatile trading environment, investing time in accurate, high-quality, and regular scenario planning can help you ensure you’re prepared for whatever happens, wherever it happens – and ultimately gain a strategic advantage on your competitors.

How Flexport Can Help

Prepare your business for the future, today. Contact us to book a scenario planning consultation tailored to your most pressing challenges.

Also, make sure to follow our regular scenario planning webinars, and look out for the upcoming volumes of this scenario planning series.

Ship anywhere. Sell everywhere. Grow faster. Flexport powers your supply chain from factory floor to customer door with visibility, control, unified communication and a team of experts who help you get it done. Freight-forwarding, fulfillment, customs brokerage and order management, all in one platform.

The contents of this e-book are made available for informational purposes only and should not be relied upon for any legal, business, or financial decisions. We do not guarantee, represent, or warrant the accuracy or reliability of any of the contents of this ebook because they are based on our current beliefs, expectations and assumptions, about which there can be no assurance due to various anticipated and unanticipated events that may occur. This ebook has been prepared to the best of our knowledge and research, however, the information presented herein may not reflect the most current regulatory or industry developments. Neither Flexport nor its advisors or affiliates shall be liable for any losses that arise in any way due to the reliance on the contents contained in this report.